-

在线留言

发送您的问题或需求,我们将尽快与您取得联系!

×

-

GETTING TO THE HEART OF PRECISION

CMT CYCLE STEP, A NEW WELDING PROCESS VARIANT

07/27/2020

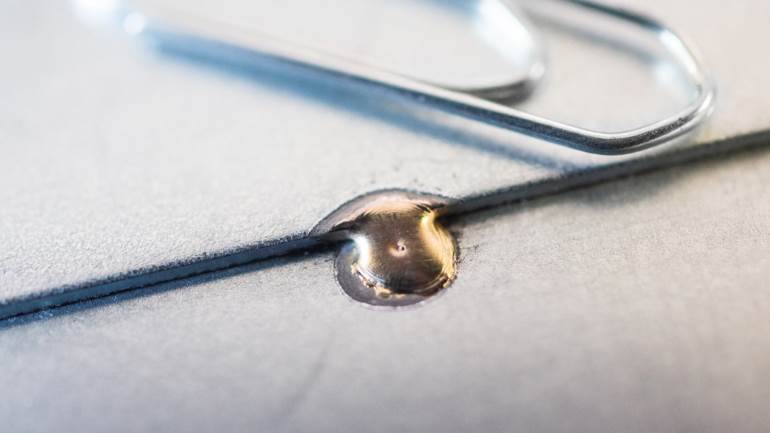

With Cycle Step, Fronius has developed a new variant for the “cold” welding process CMT (Cold Metal Transfer). The special feature is that users can set both the number of individual droplets per welding spot and the pause time between cycles. This allows the highest possible degree of precision and reproducibility, as well as a flawless weld seam appearance.

he new process variant Cycle Step is based on CMT, the MIG/MAG welding process developed by Fronius that is characterized by low heat input. When melting the welding wire, digital process control assists droplet detachment by moving the wire forwards. The transfer of the droplet to the weld pool produces a short circuit, prompting the control system to pull the wire back again. The arc ignites once again, and a new welding cycle begins.

With Cycle Step, users now have the opportunity to control these cycles in detail. Both the exact number of droplets per welding spot and the pause time between the individual cycles can be precisely defined. The welder can therefore produce spots of any size and reproduce them precisely – a totally new level of control over the welding process.

IDEAL FOR HIGH-QUALITY VISIBLE SEAMS

Heat input is also minimal with Cycle Step, and can be effectively controlled. This allows even the thinnest of metal sheets to be joined and is particularly useful for position welding with gap tolerances. The defined welding cycles also ensure visually perfect seams with clear rippling, without reinforcement or spatter, making Cycle Step ideal for high-quality visible seams. The process variant also enables the smallest fixation points to be welded and is therefore an alternative to spot welding guns. Even fine overlay welding and applications in additive manufacturing can be implemented with Cycle Step.

In the automotive industry, Cycle Step is already being successfully used in body construction, namely for fixing the so-called folding flanges of front hoods and tailgates, as well as doors. Galvanized sheet steel parts that used to be bonded together are connected by individual fixation points. This saves time during production, as the components can then be painted immediately, without first waiting for the adhesive to cure. Strictly speaking, this process is not a welding operation, but is instead a form of brazing. The spots consist of a copper silicon alloy, which is applied to the joint using Cycle Step. Before being painted, they are usually covered in PVC, so that they are no longer visible later on.

COST-EFFECTIVE, SPACE-SAVING AND VERSATILE

Manufacturers have strict demands: the fixation points must be as small as possible and extremely flat, but the sheet metal parts must nevertheless be firmly and securely connected. As hoods, tailgates, and side doors are visible bodywork components, the process must also be as spatter-free as possible. With the new Cycle Step process variant, the perfectly coordinated brazed joints ensure durable and visually perfect metal sheet fixation until the adhesive has cured in the paint oven. The investment costs are far lower than for the welding process previously used, and because the welding system does not require much space, users can operate far smaller production cells. The welding process is suitable both for steel and aluminum sheets, and is therefore highly versatile.

Cycle Step is available for the latest generation of Fronius TPS/i power sources and can be used for all CMT characteristics. A software update makes it easy to upgrade existing TPS/i welding systems with the new process variant.

-

下载

下载

会员中心

会员中心

收起

收起